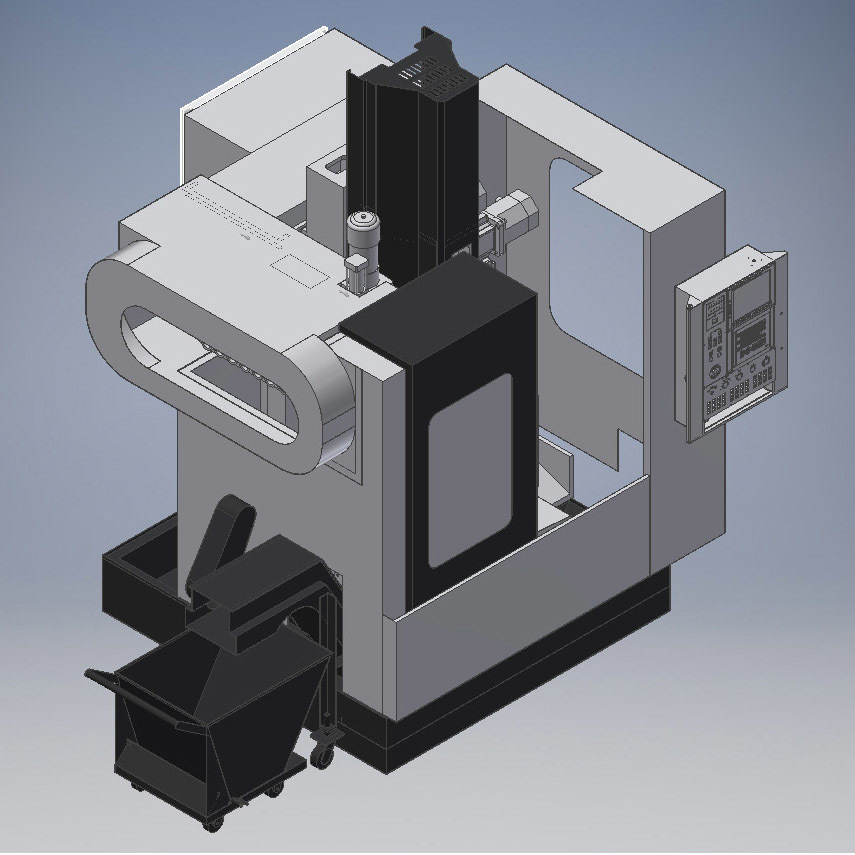

U-25

5 Axes Vertical Machining Center

The manufacturer reserves the right to modify the design, specifications, mechanisms, etc. to improve the performance of the machine without prior notice. All the specifications shown above are just for reference.

· Meehanite cast structure keeps long-term accuracy.

· Rotary table and integral 5 axes motion saddle.

· MANUAL GUIDE i 3D movement tool route graphic coordinate display.

· Spindle Speed : 12000 rpm

· Max. workpiece : Ø250 x 200 mm

| ITEM/MODEL | UM-25 | ||

| Controller | FANUC 0i-M | ||

| SPINDLE | |||

| Spindle speed | rpm | 12000(15000) | |

| Spindle nose taper | BT40 | ||

| Bearing inner diameter | mm | 70 | |

| Drive system | Direct | ||

| TRAVELS | |||

| X-axis travel | mm | 500 | |

| Y-axis travel | mm | 400 | |

| Z-axis travel | mm | 550 | |

| A-axis travel | degree | -120 / +30 | |

| C-axis travel | degree | 360 | |

| TABLE | |||

| Max. speed of rotary axis (C-axis) | rpm | 100 | |

| Max. speed of tilting axis (A-axis) | rpm | 50 | |

| Max. table loading at 0° | kg | 60 | |

| Max. table loading at 90° | kg | 50 | |

| Spindle nose to table | mm | 100~650 | |

| Table dimension | mm | Ø250 | |

| Max. workpiece size | mm | Ø250 x 200 | |

| T-slot size | mm | 12 | |

| FEED RATES | |||

| X-axis Rapid Traverse Rate | m / min | 32 | |

| Y-axis Rapid Traverse Rate | m / min | 32 | |

| Z-axis Rapid Traverse Rate | m / min | 30 | |

| Cutting feed rate | m / min | 12 | |

| Ball screw diameter (X/Y/Z) | mm | 45/45/45 | |

| Guideway type | Roller | ||

| AUTOMATIC TOOL CHANGE SYSTEM | |||

| Tool magazine capacity | pcs | 32 | |

| Max. tool weight | kg | 7 | |

| Max. tool diameter | mm | 80 | |

Max. tool diameter without adjacent tools | mm | 150 | |

| Method of tool exchange | Arm type | ||

| Max. tool length | mm | 300 | |

| MOTOR | |||

| Spindle motor power(Cont. / 30min) | kW | 7.5 / 11 | |

| X/Y/Z feed motor | kW | 3/3/4 | |

| Coolant pump motor(50Hz/60Hz) | kW | 0.53+0.85/0.75+1.27 | |

| OTHERS | |||

| Air supply | kg/cm² | 5.5 | |

| Machine dimension L x W x H | m | 2 x 2.5 x 3 | |

| Net weight | kg | 5000 | |

| NO. | STANDARD ACCESSORIES | NO. | OPTIONAL ACCESSORIES | |

| 1 | FANUC 0i-M controller +AICC I | 1 | Data server 2G | |

| 2 | RS-232 interface | 2 | Linear scale (Heidenhain) | |

| 3 | Rigid tapping | 3 | Contact tool setter | |

| 4 | Heat exchanger for electric cabinet | 4 | Workpiece touch probe | |

| 5 | 8.4″ Colored LCD monitor | 5 | Air cooler for electric cabinet | |

| 6 | Lubrication system | 6 | Spindle speed upgrading | |

| 7 | 4-bar coolant system | 7 | Upgrade to 10.4″ Colored LCD monitor | |

| 8 | Cutter air blast | 8 | 20 bar coolant through spindle system /td> | |

| 9 | Spray gun | 9 | Oil-coolant skimmer | |

| 10 | Three-color warning light | 10 | Oil mist collector | |

| 11 | Spindle oil cooling system | 11 | Automatic door | |

| 12 | Chain type chip conveyor + chip cart | |||

| 13 | Transformer | |||

| 14 | CE version | |||