HS-630i

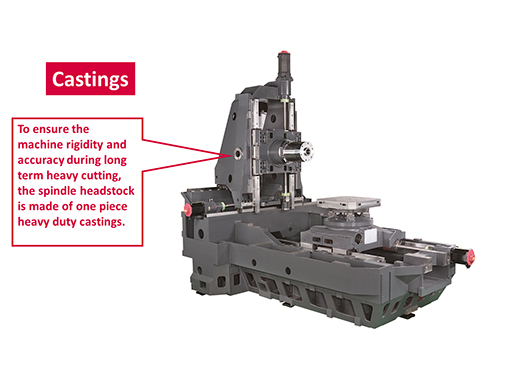

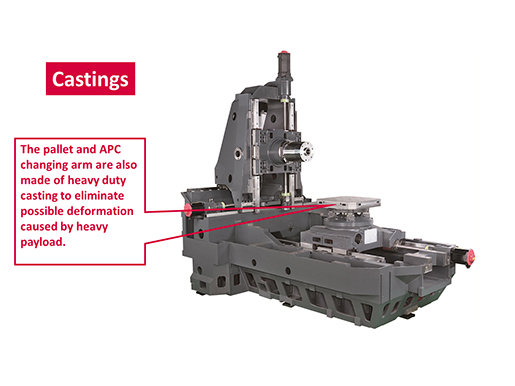

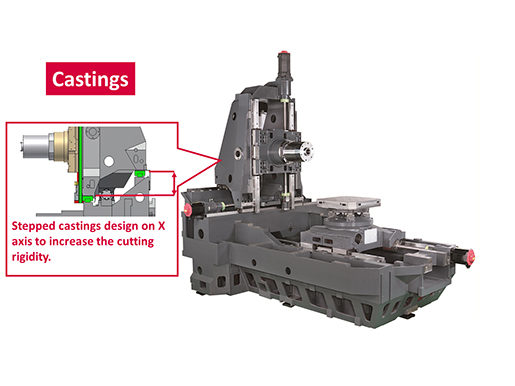

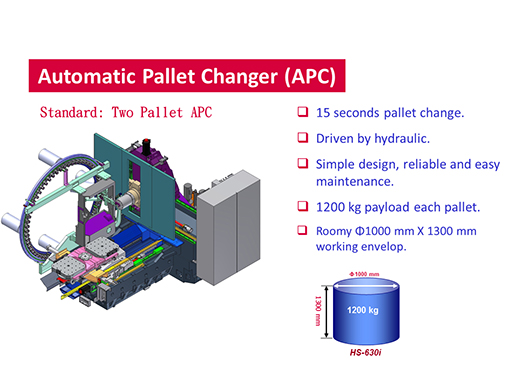

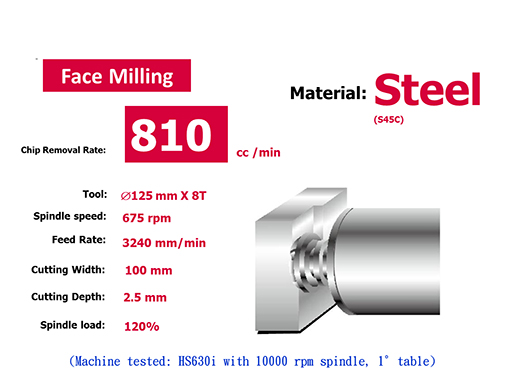

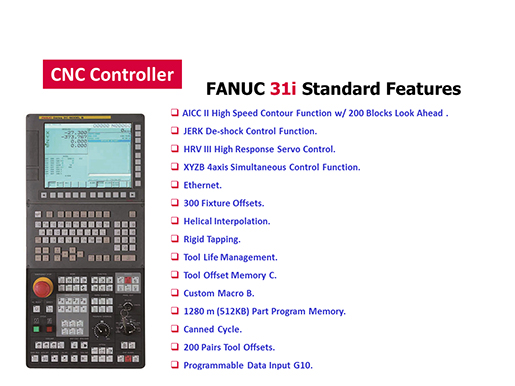

Horizontal Machining Center HS-630i is developed with ψ1, 000×1,300 mm work envelops, driven by FANUC 31i- MB controller and featuring with the 200 block look ahead function. The HS-630i Horizontal Machining Center can achieve optimal traveling range 1,050mm×900mm×1,020mm, thus offering an even higher speed processing capacity.

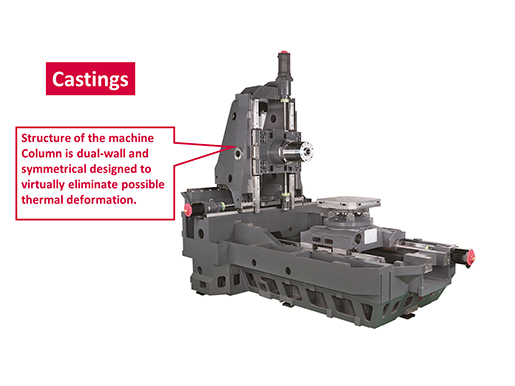

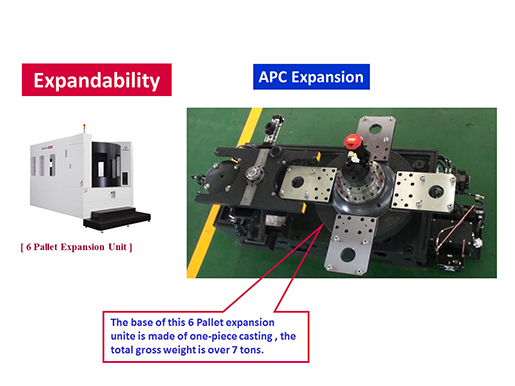

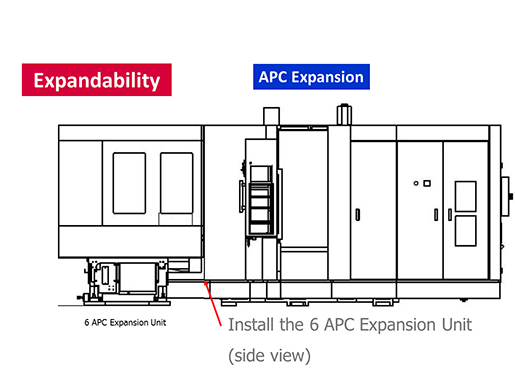

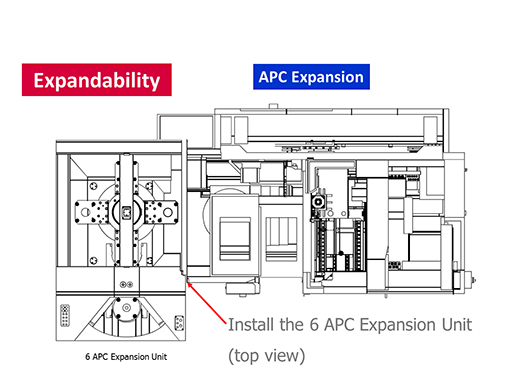

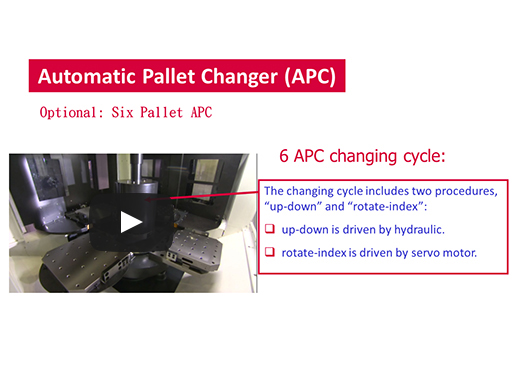

It is packed with innovative technology and high quality. The Dual-one machining center enables HS-630i with superior expendability, great efficiency and longer lifespan by operating the proven technology and environment friendly concept. Averex provides customers with highly advanced and reliable machining centers that are in compliance with CE regulations.

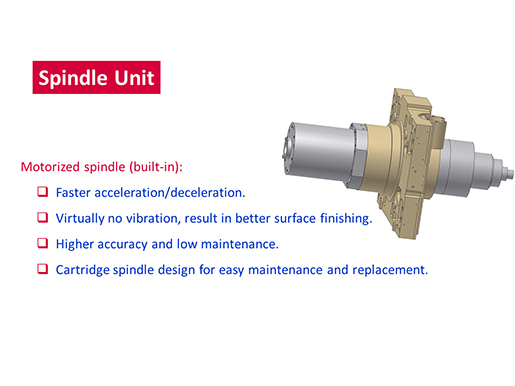

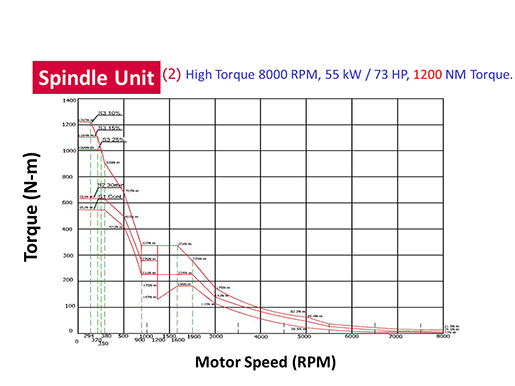

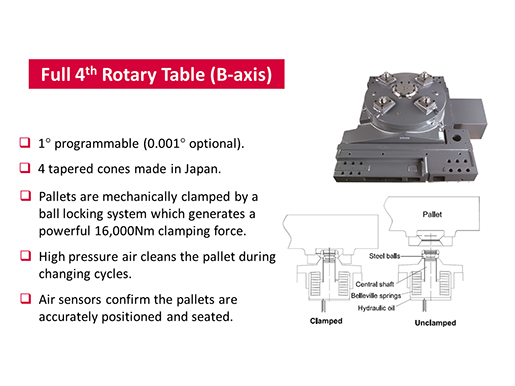

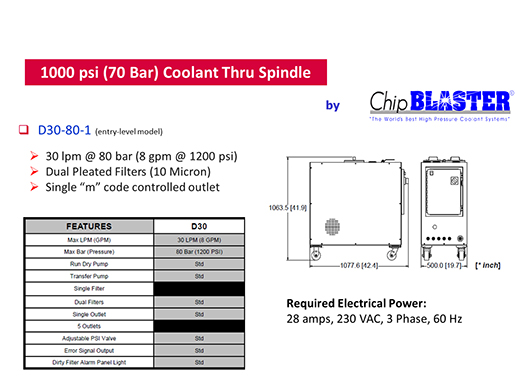

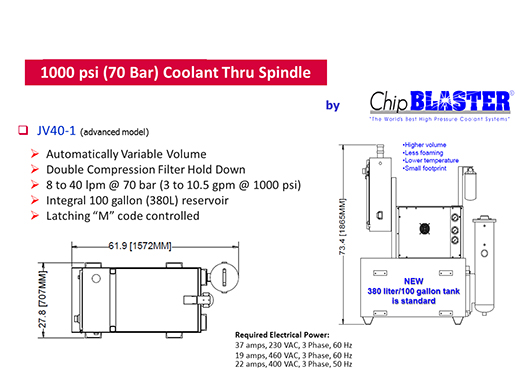

Also included in the series, highlights the TSC (Thermal Control System) system, which consists of a measuring probe for temperature and a cooler built into the machine, and which are responsible to constantly supply oil to a temperature-controlled both the spindle and other critical elements of the maquina.a up to 200 Nm (2 min) and 150 Nm (15 min) and 4th axis with 0.001 ° indexing.

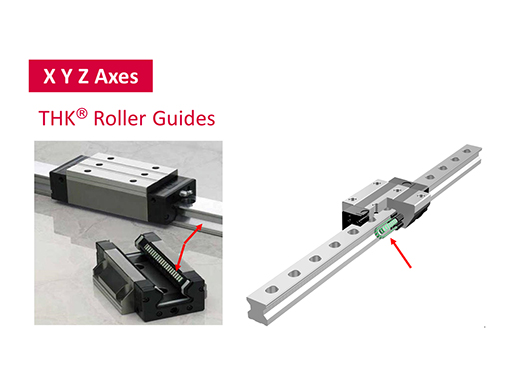

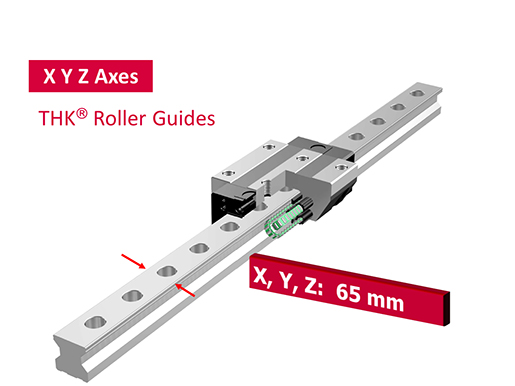

The machine is equipped also with roller guides and all the linear axes (X, Y, Z) have an acceleration and deceleration of 1G.

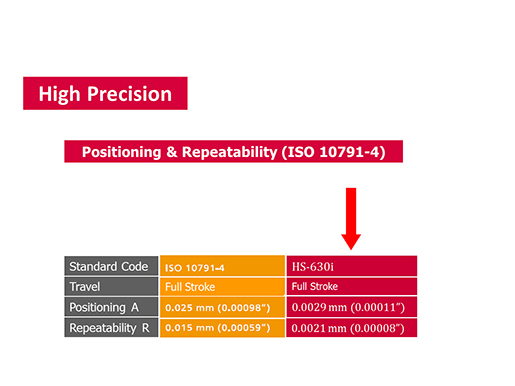

Also included in series, highlights the TSC (Thermal Control System) system, which consists of a measuring probe for temperature and a cooler built into the machine, and who are responsible to constantly supply oil to a temperature controlled both the spindle and other critical elements of the machine. The TSC incorporates a lubrication system for spray air / oil pressure which provides lubrication required for ball, roller screws guidance and spindles bearings, maintaining accuracy in machining a repeatability of 0,002032 mm and 0,00254 mm