Tool Grinding Machines

GT series Tool grinding machine can be used for grinding drills, end mills and all kinds of tools. Max. tool diameter can reach 120mm and 150mm. It is the best solution to regrinding and manufacturing of all kinds of tools. The main features are as follows:

- Worldwide-patented 5-axis design. B-axis rotary column are supported by high-rigidity bearings. Can stabilize the free movement of the grinding wheel spindle, ensure the compact grinding procedures.

- Can complete measuring, multi-process shape processing and Radius grinding in one clamping.

- Use pneumatic grinding wheel arbour HSK clamping system can keep the concentricity of grinding wheel in 3μm.

- Use Rexroth MTX micro / NUM-Flexium Controller and 3D tool grinding software MTS / NUMROTO.

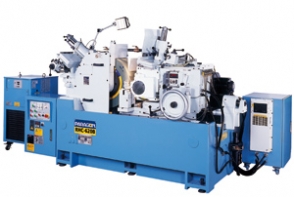

Centerless Grinding Machines

The RC series centerless grinding machines can be used for infeed grinding and thrufeed grinding to ensure accuracy, high productivity in workpieces with diameters between 1 mm and 50 mm. Automatic loading and unloading attachment is convenient to operate and reduce cost. The main features are as follows:

- The grinding and regulating wheel spindles are made of high quality alloy steel (SNCM-439), and treated through: normalized, tempered, carburized hardening, sub-zero treatment, and then follows the precision grinding process which can greatly enhances spindle life and stability guaranteeing deformation free performance.

- The unique hydrostatic bearings of the grinding wheel and roller bearing of regulating wheel can reduce the metal friction.

- The machine base is manufactured from high quality Meehanite cast iron and analyzed by advanced Finite Element Method (FEM).

- Along with vibration stress release, these outstanding structural features assure high strength, maximum damping capability, and longer service life.

Total solution. Automatic grinding process design.

High-Speed Centerless Grinding Machines

RHC Series not only with the features of centerless grinding machine but also with design of spindle fixed elements, which is double support, big span and like hugging. It’s not only to improve stiffness, but also make sure the stability of the spindle under heavy cutting.

- Roller and Ball Bearings Series (B Series)

The innovative advanced regulating wheel spindle does not require a flange and utilizes angular contact bearings and cylindrical roller bearings with double supports that firmly maintain spindle super precision rotation and rigidity. - CNC Series

Available with roller and ball bearings.

Equipped with FANUC color screen, the latest technology in digital control systems.

Internal Grinding Machines

The RIG series internal grinding machine is suitable for inner diameter of workpiece. The efficient and reliable programming of grinding and dressing cycles is suitable for mass production and ensures the precise concentricity on inner diameters. The main features are as follows:

- Nimble and precise positioning wheelhead.

- Multi-function and manual adjustable workhead.

- Highly rigid machine base with hydrostatic lubrication on guideways on Z axis.

- Heidenhain sub-μLinear scale with closeloop feedback on X axis.

CNC Angular Cylindrical Grinding Machines

Angular cylindrical grinding machines designed by PARAGON are suitable for long, multi-steps, and profile cylindrical grinding, up to 0.1 μm positioning accuracy, which offer the best choice for high accuracy.

Universal Cylindrical Grinding Machines

The GU Series are compact universal cylindrical grinding machines by PARAGON, and can achieve up to 0.1 μm positioning accuracy. They are suitable for long, multi-steps, and profile cylindrical grinding. Along with the optional internal grinding unit attachment, they provide more flexibility and offer the best choice for your needs. The main features are as follow:

- Grinding wheelhead spindle with unique Hydrostatic Bearings

- Multi-function, high roundness Workhead

- Hydraulic and manual adjustable Tailstock

- High rigid Machine Base with Hydrostatic Lubrication on guideways

- Heidenhain sub-μm Linear Scale with closeloop feedback.

Polygon Grinding Machines

Ultra GU-3550CNC is the ultra design for both eccentric and non-round grinding. Applications include eccentric, polygon, camshaft, and crankshaft parts grinding, etc

Hydraulic Surface Grinders

Victor precision hydraulic surface grinders are manufactured to highest quality with unsurpassed precision and reliability.