HS-450i

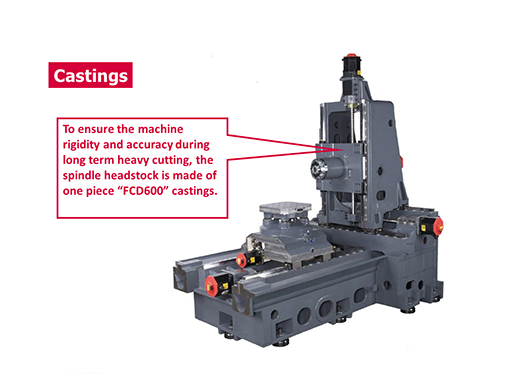

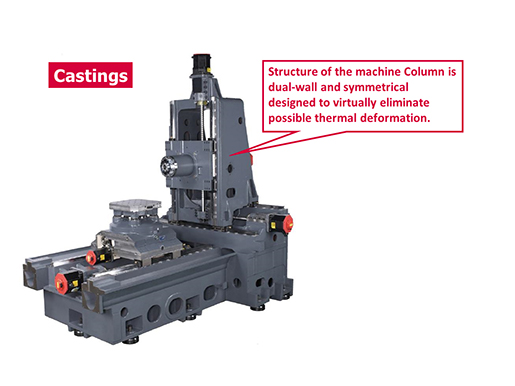

is especially built for high speed and high precision machining. TCS will virtually eliminate the thermal deformation and maintain the speed and precision during long term operation,

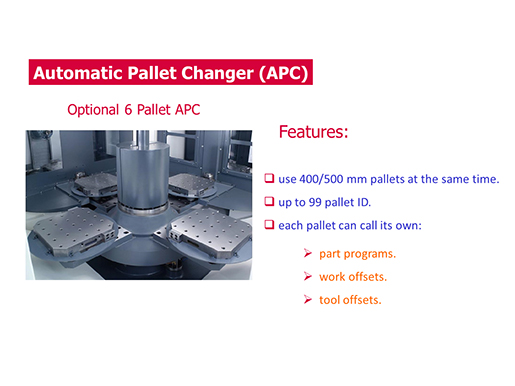

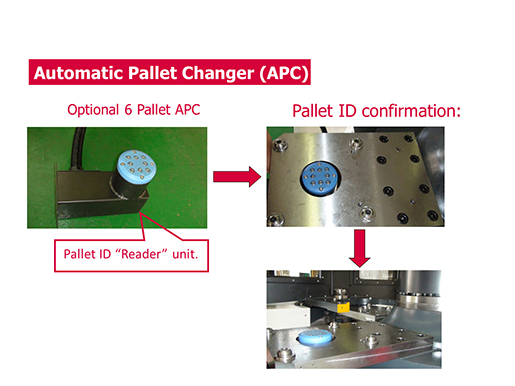

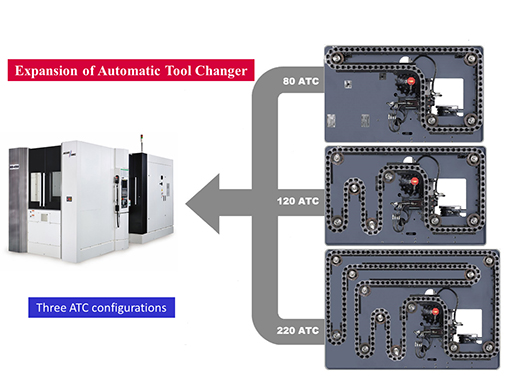

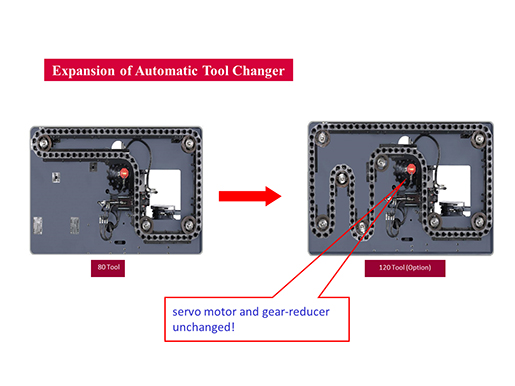

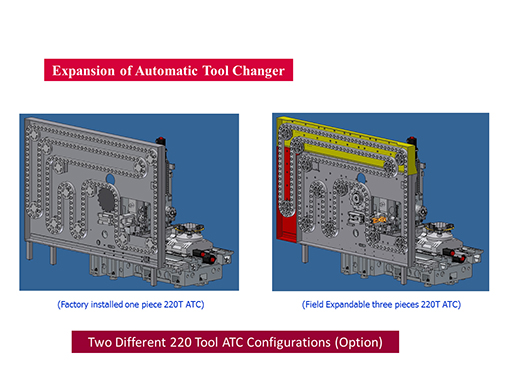

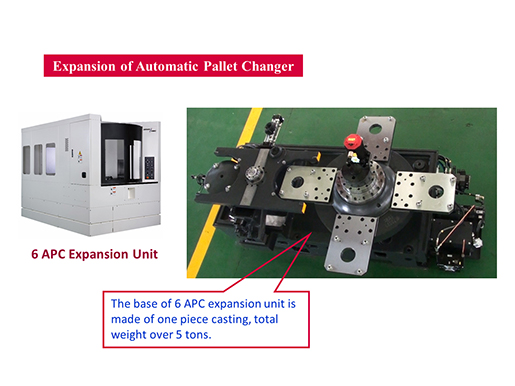

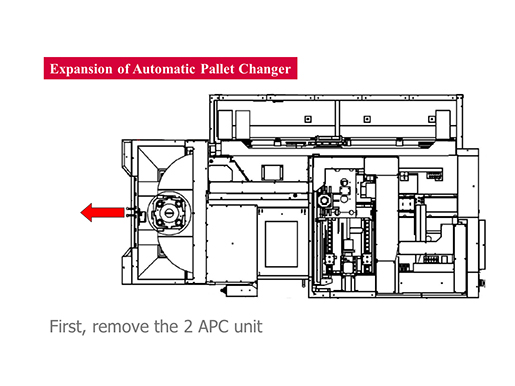

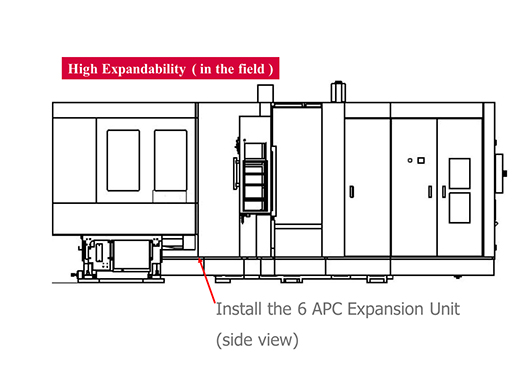

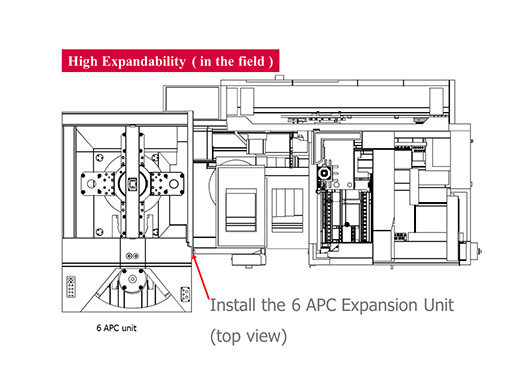

MC HS-450i luminometer (just like his older brother, the HS-630i) has the unique ability to be a horizontal mechanized expandable, that allows to convert a machine 2 pallets and 80 tools in one of 6 pallets and 120 or 220 tools, and this once the machine already it has been installed and a fast and simple way (in two days).

HMC HS-450i luminometer (just like his older brother, the HS-630i) has the unique ability to be a horizontal mechanized expandable, that allows to convert a machine 2 pallets and 80 tools in one of 6 pallets and 120 or 220 tools, and this once the machine already it has been installed and a fast and simple way (in two days). machine 2 pallets and 80 tools in one of 6 pallets and 120 or 220 tools, and that once the machine has been installed and a fast and simple way (in two days).

| Model & Speed | HS-450i |

| 15,000 RPM | 7 sec Pallet Change |

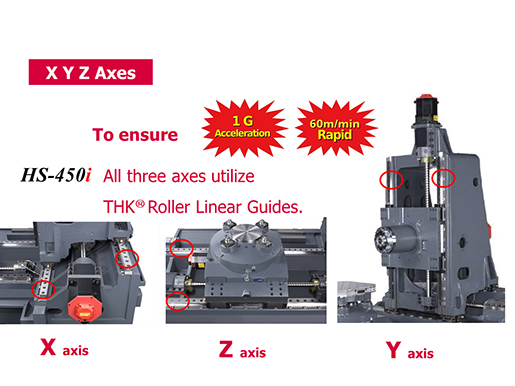

| 1G Acceleration | 60m/min RAPID |

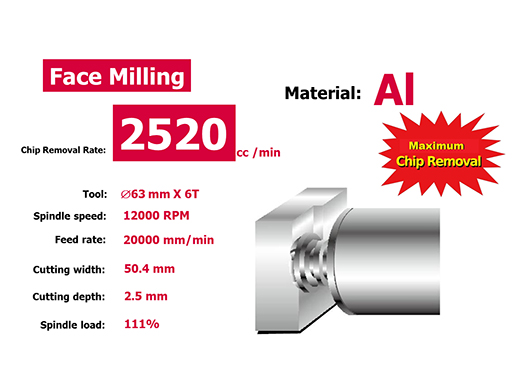

| 1 sec T-T Change | 2,520 cc/min Chip Removal |

Also included in the series, highlights the TSC (Thermal Control System) system, which consists of a measuring probe for temperature and a cooler built into the machine, and which are responsible to constantly supply oil to a temperature-controlled both the spindle and other critical elements of the maquina.a up to 200 Nm (2 min) and 150 Nm (15 min) and 4th axis with 0.001 ° indexing.

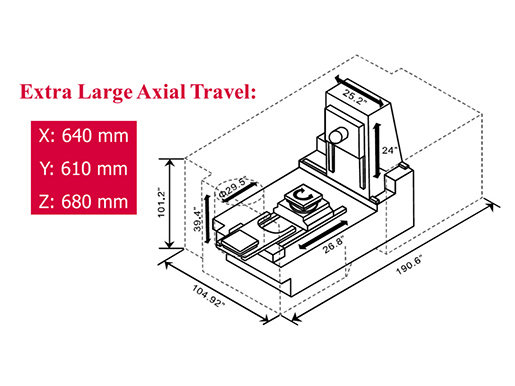

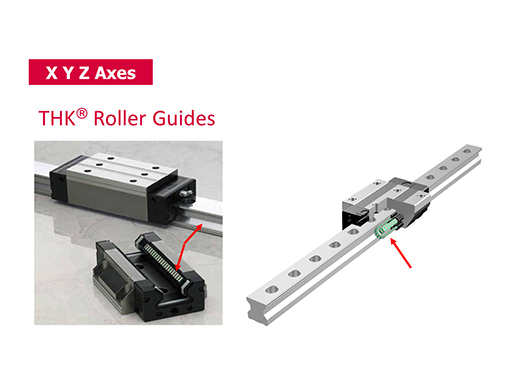

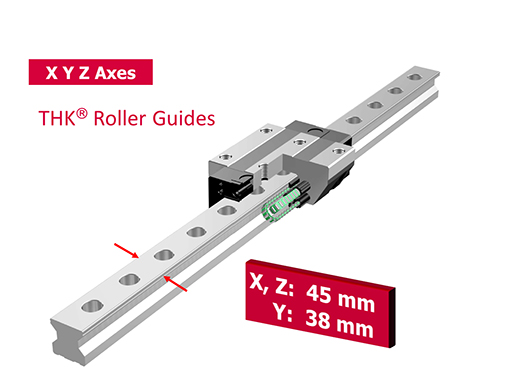

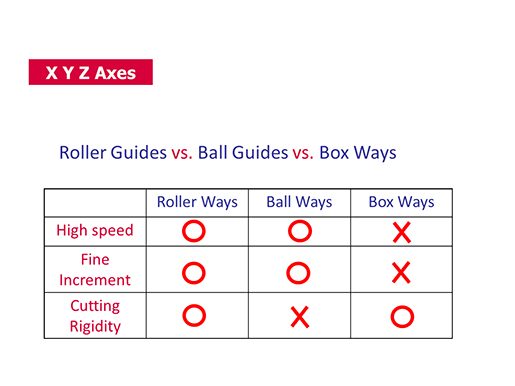

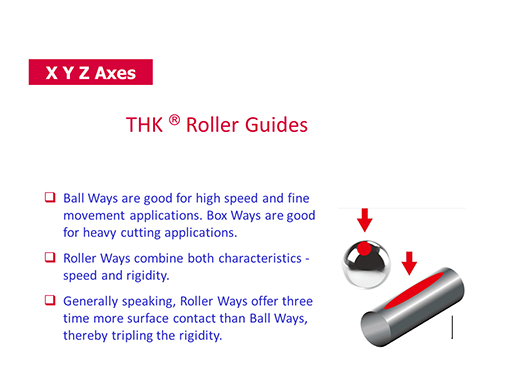

The machine is equipped also with roller guides and all the linear axes (X, Y, Z) have an acceleration and deceleration of 1G.

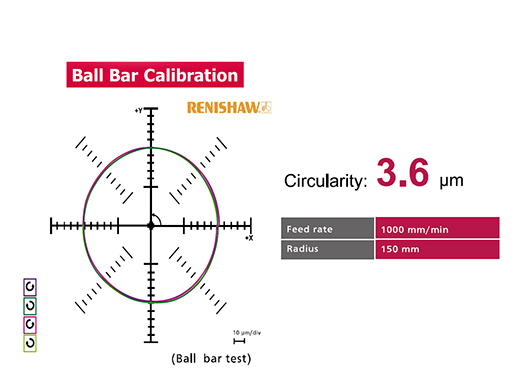

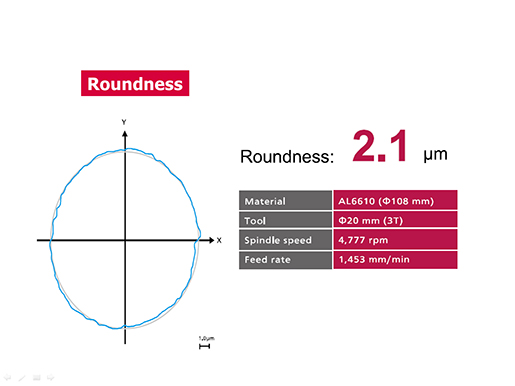

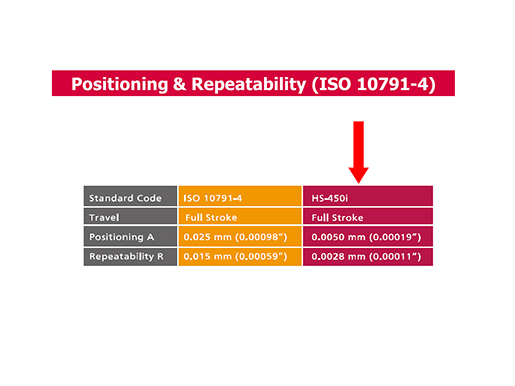

Also included in series, highlights the TSC (Thermal Control System) system, which consists of a measuring probe for temperature and a cooler built into the machine, and who are responsible to constantly supply oil to a temperature controlled both the spindle and other critical elements of the machine. The TSC incorporates a lubrication system for spray air / oil pressure which provides lubrication required for ball, roller screws guidance and spindles bearings, maintaining accuracy in machining a repeatability of 0,002032 mm and 0,00254 mm